GC50

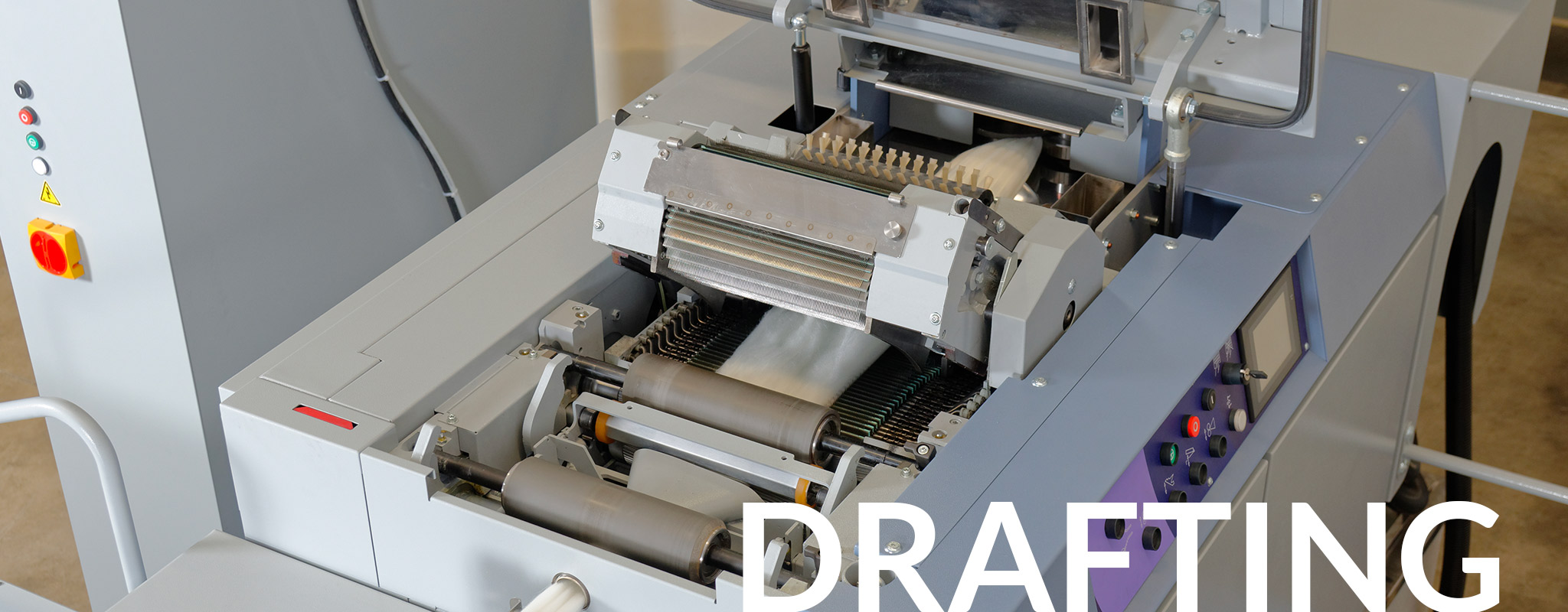

The mechatronic chain gill

The new generation 50 of chain gills is built on mechatronic technology which facilitates use and maintenance.

The major interest of this mechatronic technology is to reduce mechanical settings and operator interventions. That is why many settings are electronically controlled now in order to enhance precision and responsiveness.

For example, the setting of the nip distance can be modified electronically as can several tensions. It is simple to use and more reliable.

Another aspect is the suction system. Filter bags have replaced the traditional suction box which facilitates cleaning. The filter surface is larger and the suction power can be modified. All these innovations make the machine cleaner in order to maximise textile quality during production.

Another innovation is the new control screen. The larger 15” screen allows a lot of information to be displayed in real time. The documentation relating to the machine is now available via the screen as is useful production data or power consumption information.

The number of mechanical rotating parts has been reduced, which means maintenance is less time-consuming and fewer mechanical issues are possible.

Like the other machines in the 50 series, the GC50 is ready for Industry 4.0 with comprehensive data collection.

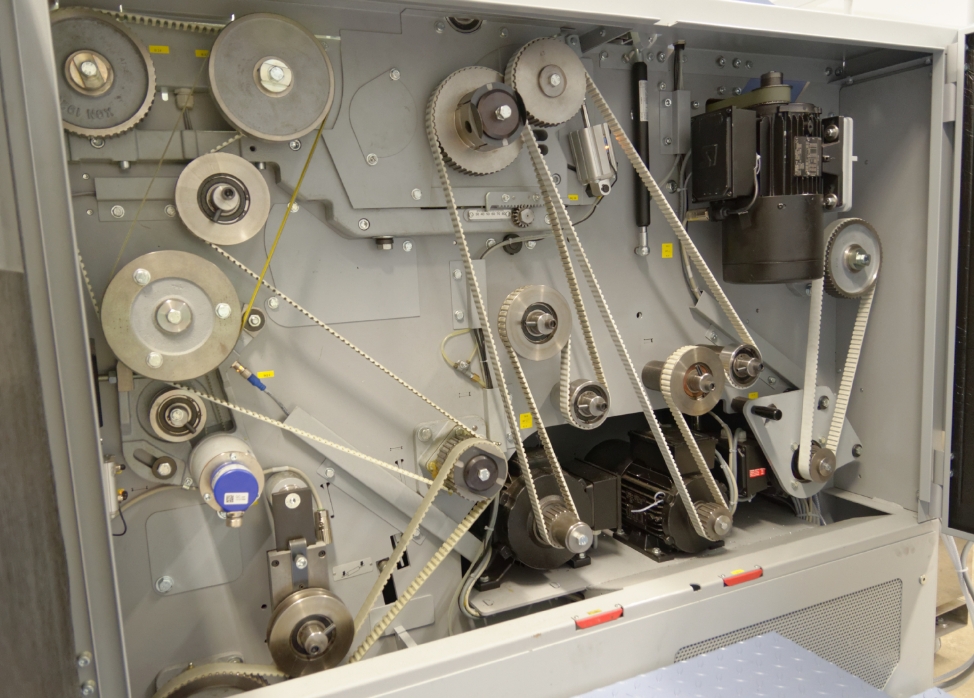

GC40

High performances with a chain gill head

The use of pins is necessary for the drafting of heavy loads of wool and long fibres.

The pin path has a major influence on the machine’s performance and on the quality of the slivers produced.

The GC40 chain gill is equipped with a pinned head with chain driven fallers allowing a very high operating speed.

The GC40 chain gill features a new ergonomic which simplifies the accessibility to its head. It also improves the machines service and its maintenance.

The GC40 chain gill fulfils the modern textile world needs by:

![]() Its great adaptation capacity, thanks to its wide range of creels and its multiple deliveries

Its great adaptation capacity, thanks to its wide range of creels and its multiple deliveries![]() Its possibilities of options (auto-levellers, threaders, sprayers)

Its possibilities of options (auto-levellers, threaders, sprayers)![]() Its specific arrangements (defelting, mixing, linkage)

Its specific arrangements (defelting, mixing, linkage)

The GC40 processes wool, long staple chemical fibres, flax tow in all fields such as converting, stretch breaking, combing, recombing and preparation of spinning.

To properly control the significant length dispersion, the best solution is no doubt the double pinned field with fallers, and it is this technique that n. schlumberger optimized with the GC40.

The GC40 is equipped with a cleaning system with preprogramed cycles ensuring a constant and durable textile quality.

The GC40 chain gill is:

![]() User friendly

User friendly![]() Highly automated

Highly automated![]() Energy efficient and

Energy efficient and![]() Has low operating and maintenance costs and is therefore more cost effective.

Has low operating and maintenance costs and is therefore more cost effective.

GN8

Screw type drafting head

Our classical GN8 intersecting machine constitutes one of the drafting systems from n. schlumberger.

The GN8, featuring a head with fallers controlled by screws and cams, processes wool, long staple synthetic fibres and flax tow. It is particularly well suited to processing fibres with very low cohesion. It is also suitable for small batch units.

An essential part of the GN8, the drafting head elements are built and assembled with particular care.

The head is comprised of a double pinned field with fallers driven by double threaded screws. The screws and their bearings are lubricated by an automatic system with a control device.

Designed in order to preserve the fibres, the GN8 offers performance and characteristics appreciated by its users: robustness, simplicity of the adjustments, safety systems allowing operation at the highest speeds.

The GN8 intersecting machine can be adapted with an autoleveller. Feeding the GN8 and delivery can either be done by balls or cans with or without detour rollers.

GV20

The essential element of the fine yarns preparation units

The GV20 vertical gill is a high speed vertical drafting machine. It is designed to produce light slivers to feed in a rational way the finisher before fine yarn spinning. The GV20 is proposed with two or four heads.

The vertical gill can be equipped with two different types of drafting systems which enable it to extend its field of application to the finest fibres and at the same time improve the sliver quality.

Pinned drafting system:

It is comprised of a double field of pinned fallers driven by double roller chains. It is intended for producing slivers from 2 to 8 ktex.

Apron drafting system:

It is comprised of a wide rubber apron on the rear part and two control barrels on the front part. The feed cylinder and the control system are adjustable in height so that the distances can be adapted to the material processed. It is more especially intended for processing light slivers 2 to 5 ktex.

The GV20 is also used as third and fourth passage of preparation. The vertical arrangement of the working elements above the delivery, the short and rectilinear path of the slivers at the delivery, the ease of access to the creel and the automatic delivery give the GV20 high speed drafter an innovative and consistent user experience.